Wholesale New Fashion Design for Laser Machine Dust Collector -Sinter Plate Filter Media

XDHD is a famous company in the design and manufacture of Laser Machine Dust Collector.

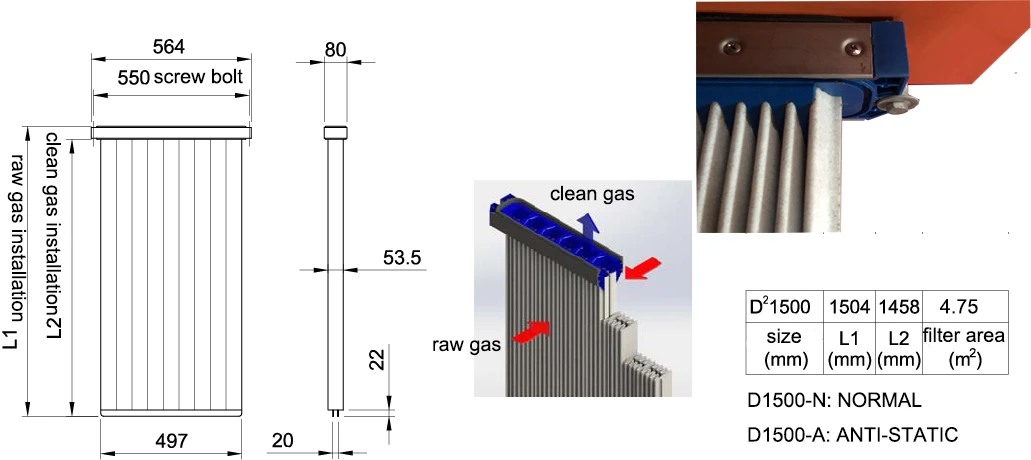

XDHD Delta2 Plate Filter Elements

Replacement Delta2 type. Sintered Filter Media Panels filter technology bases on pure surface filtration. It sustainably protects man and machine from harmful production emissions and enables absolutely sort- and contamination-free material recovery. This increases directly your productivity.Lowest clean gas values, absolutely constant operating conditions, highest availability and energy efficiency are key features of the innovative technology. Sintered PE Surface filter elements show extreme durability and, depending on the process, long service life times of more than 15 years. Thereby the filters make a valueable contribution to environmental protection and sustainability.Sintered PE Surface filter elements have proven themselves for decades in effective and safe particle separation in almost all areas of industry . Even with finest grain sizes, energy-efficient air recirculation is possible in most cases, proven even with toxic dust.

Features/Advantages

Sintered Filter Media Panels filter technology bases on pure surface filtration. It sustainably protects man and machine from harmful production emissions and enables absolutely sort- and contamination-free material recovery. This increases directly your productivity.

Lowest clean gas values, absolutely constant operating conditions, highest availability and energy efficiency are key features of the innovative technology. Sintered PE Surface filter elements show extreme durability and, depending on the process, long service life times of more than 15 years. Thereby the filters make a valueable contribution to environmental protection and sustainability.

Sintered PE Surface filter elements have proven themselves for decades in effective and safe particle separation in almost all areas of industry . Even with finest grain sizes, energy-efficient air recirculation is possible in most cases, proven even with toxic dust.

Product Advantages:

Longest service life of sintered plates up to 10 years

Long service life, relatively low maintenance and consumables costs

Optimized geometry reduces pressure drop

Increased pleats in each chamber significantly increase filter area

Constant pressure drop keeps airflow constant, helping to improve equipment efficiency

Surface filtration for high separation efficiency

Monoblock sintered plate design for compact rigidity

Suitable for abrasive dusts

Completely fiberless filter media, ideal for product recovery

Can be cleaned, recycled, and refurbished

Can be provided with anti-static or non-anti-static sintered plates

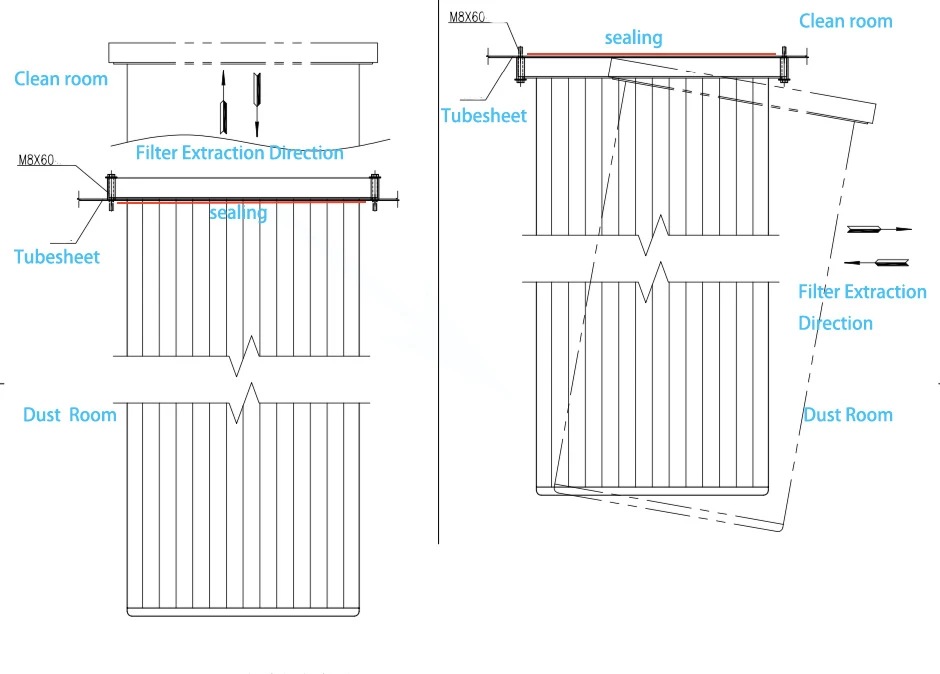

Can be installed from either dirty gas or clean gas side

Can be installed horizontally or vertically

Technical Data

For example, Delta2 1500 AT1 means length1500mm, anti-static, less than 70°C filter element.

Applicable Fields

XDHD Delta2 Plate Filter Elements